I have just finished a 2-week trip visiting Compac and TOMRA customers in Chile and the United States. I always enjoy visiting customers – it’s a great opportunity to see our sorting technology in action and the positive impact it’s having on food producers. It’s also fascinating to see first-hand the changes between visits and the effects global food trends are having on these businesses.

The biggest change I saw this time was how our customers are using data to improve their productivity. I was pleasantly surprised when Tim Sambado, owner of Prima Frutta, described his family run cherry, apple and walnut production company as an ‘information company’. He said, “Our investment in technology is an investment in information.”

In addition to using our technology to keep track of weight, shape, color and defects, Prima Frutta invested recently in Inspectra2, to help them gather data about the internal characteristics of their fruit. They collect millions of bytes of information about each individual piece of fruit that goes through their packhouse, then they use it to determine which pack, and ultimately which market, that fruit should go into.

In addition to using our technology to keep track of weight, shape, color and defects, Prima Frutta invested recently in Inspectra2, to help them gather data about the internal characteristics of their fruit. They collect millions of bytes of information about each individual piece of fruit that goes through their packhouse, then they use it to determine which pack, and ultimately which market, that fruit should go into.

It is a very different picture from the one that springs to most minds when we talk about the day-to-day business of a third-generation fruit packer. But data is leading the food industry in a whole new direction, and fast.

The changes that digital data is bringing to the food industry

When a consumer buys fruit in a supermarket, how that fruit arrived there from the farmer is probably not what they’re thinking about. And why would it be? Our industry works very hard to create a world where the seasonality of fruit and vegetables is no longer an issue. Kiwifruit all year around? Not a problem. But how do people think this is possible, without a lot of technological and logistical intervention?

The popular misconception that fresh foods are produced in an old-fashioned way still persists. Aside from the odd tractor or plough, technology is not something the average consumer associates with the food industry. While traditionally run food producers still exist, they are certainly not the standard anymore and are becoming less over time.

The popular misconception that fresh foods are produced in an old-fashioned way still persists. Aside from the odd tractor or plough, technology is not something the average consumer associates with the food industry. While traditionally run food producers still exist, they are certainly not the standard anymore and are becoming less over time.

In reality, the food industry is under tremendous pressure to feed a growing global population with a finite amount of resources. Food producers are also innovators, looking for new ways of using information and technology to increase yield and combat the effects of labor scarcity. Smart use of data can also help with the monitoring and predictive maintenance of sorting equipment, improve food safety, accurately measure production line variables such as throughput and pack-out.

How food industry innovators are improving yield, quality and performance with data

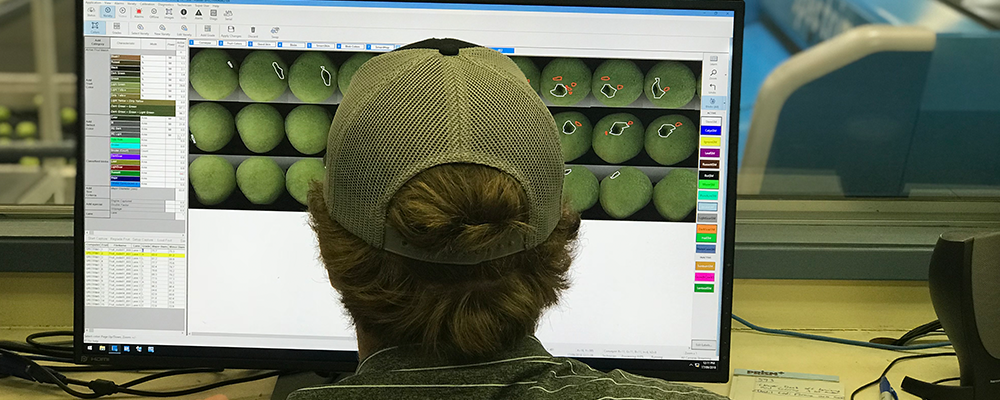

At Prima Frutta, in Linden, California, I spent time talking to John Cunha who is the operator of their apple line. John is responsible for the external and internal grading of their apples. He spends the majority of his time in front of a computer, tweaking Spectrim and Inspectra2 software.

At Prima Frutta, in Linden, California, I spent time talking to John Cunha who is the operator of their apple line. John is responsible for the external and internal grading of their apples. He spends the majority of his time in front of a computer, tweaking Spectrim and Inspectra2 software.

Most of John’s friends know he works in agriculture, but assume he picks cherries for a job. In reality, John is controlling powerful hardware and utilizing intelligent software, including machine learning and AI algorithms, to guarantee a great experience for the people who end up eating his produce.

Watch the Prima Frutta story here

Meanwhile, at Moonlight Companies of California, even sitting in reception their use of data is clear to see. A screen on the wall shows how the company measures their consumption of resources in real-time. It illustrates all the improvements in each area on a simple dashboard.

I met with David Gonzalez, Sr. Director of Operations, who showed me the main office area. It looks more like a NASA mission control (photo below) than any traditional food packing business. All the data from their entire operation is pulled into a central location, allowing for decisions to be made based on information rather than gut feeling, in real-time, rather than having to wait a day or a week. They can make fine adjustments all the time, to ensure produce on the machine is realizing maximum value at every stage of the sorting process.

Perhaps even more impressive, is the app David showed me on his phone. This app allows him to bring all the relevant data that he needs for his role into the palm of his hand. When walking around, it was easy to see precisely how data is helping Moonlight drive efficiencies and also track the key performance indicators they need to keep their business on track to meet its targets.

Read more: What is blockchain, and what does it mean for fresh produce?

Smarter use of data is disrupting all sorts of industries – and food is no different. Feeding 10 billion people by 2050 might be a challenge, but it’s also a massive opportunity for everyone involved in this increasingly innovative sector. Technology and data are going to play a huge part in our future and the ones who embrace this change will prosper.