The fresh produce industry is facing challenges that only technology can help resolve. In an age where we’re all technology adopters, we barely bat an eyelid at the incredible technological achievements humans are making globally. But when we stop to take a look, we’re making huge advancements in all areas and the fresh produce industry is certainly no exception.

It’s a certainty that in the near future the entire industry will be using technology to better their processes and production, so as a player in this industry it’s important to look at your technology options.

In this blog, we look at how technology is helping the fresh produce industry, and how technology such as Spectrim, is having a leading role in this movement.

View the guide “Repackers face the big squeeze” to read about trends facing repackers and distributors in the fresh produce industry.

The opportunity of disruption

The key sentiment presented by produce industry leaders at The Australian's Global Food Forum in March was that of the impact of disruption to agribusinesses, and a need to be agile and adaptive to succeed.

Harry Debney, CEO of Australian horticulture giant, Costa Group which completed their first season with Spectrim last year, believed that mechanization is the “Holy Grail” of the agriculture industry.

“We talk about Australia being a major exporter – and it is in beef and wheat, but it’s not so in horticulture – we’re still a niche exporter,” Debney said. “If we could mechanise most of our harvest, which is 30-50 per cent of our total production cost, we would be a global exporter on a very large scale.”1

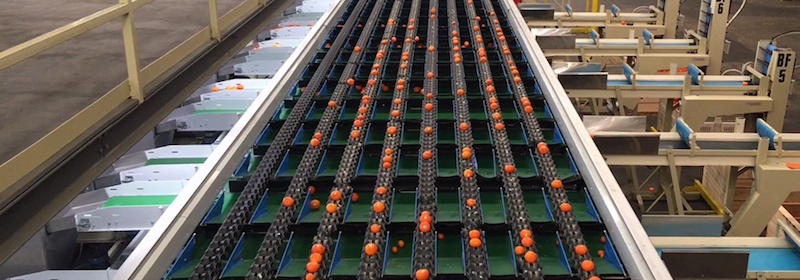

Debney said one of the major steps forward in technology was the development of sorting lines that detect color and blemishes on fruit. Costa installed the new vision sorting platform, Spectrim, which checks each piece of fruit 100 times, up from its previous sorting line technology, which checked fruit around seven times before being sorted manually.1

development of sorting lines that detect color and blemishes on fruit. Costa installed the new vision sorting platform, Spectrim, which checks each piece of fruit 100 times, up from its previous sorting line technology, which checked fruit around seven times before being sorted manually.1

“This is a real game changer,” Debney said. “It eliminates all of the labor [to sort fruit], and has given us 50 per cent throughput improvement.”1

His message was echoed in New Zealand by Mike Chapman, CEO of Horticulture New Zealand, after announcing a 40% increase in horticulture exports.

“Technology, therefore, has a significant contribution to make to the continued growth of horticulture; it is affordable and can increase production per hectare, in turn enabling further investment in technology. What a great growth cycle!”2

With this in mind, there is optimism in the fresh produce industry, and disruption must be viewed as an opportunity rather than a challenge. An opportunity, because optical fruit sorting and packhouse technology, such as Spectrim, addresses the key issues facing the fresh produce industry.

So, is it a time for change? Let's explore a few of the benefits of produce sorting and grading technology.

Labor

Labor can be challenging when it comes to the harvest and post-havest.  Whether it’s about the flexibility and cost of contracts, or finding reliable and skilled workers, technology such as Spectrim, will reduce and possibly eliminate much of the sorting labor required. This means worker availability and skill level will not affect production processes. Where once companies had sixteen staff on a produce sorting line, they now have none, leading to an increase in margins by a reduction in labor costs.

Whether it’s about the flexibility and cost of contracts, or finding reliable and skilled workers, technology such as Spectrim, will reduce and possibly eliminate much of the sorting labor required. This means worker availability and skill level will not affect production processes. Where once companies had sixteen staff on a produce sorting line, they now have none, leading to an increase in margins by a reduction in labor costs.

Protect your brand with safe quality packs

The technology has a considerable focus on food hygiene, ensuring produce is kept clean, safe and monitored constantly. Produce is processed by a inspection system that reads, monitors and records your produce to the level of being able to tell a bruise from a puncture and so on. This software is also programmable so that you can tailor it to your specific produce. You will be certain that the best produce goes into the right buyer’s box. More importantly, your brand benefits as products like Spectrim ensure your produce is healthy and perfect so that your consumers get the best product you can supply. No marks, bruises or blemishes.

Uptime

Produce sorting technology increases uptime, with equipment running for longer periods. This and the ability to easily switch between produce order types, assists you in catering to market demands and fluctuations with little, to no, interruption to operations. This allows for closer focus on margins between producer and retailer.

Welcome change

Fresh produce sorting technology is constantly evolving and will continue to make an impact on global agriculture. Change should be welcomed, and when welcomed, it affords businesses opportunities to evolve, grow and optimize.

For more information, view the guide “Repackers face the big squeeze” to read about trends facing repackers and distributors in the fresh produce industry.

Published based on the below articles:

1 http://www.fruitnet.com/produceplus/article/171807/mechanisation-the-holy-grail-for-hort

2 http://www.hortnz.co.nz/news-events-and-media/mikes-blog/technology-will-enable-horticulture-growth/